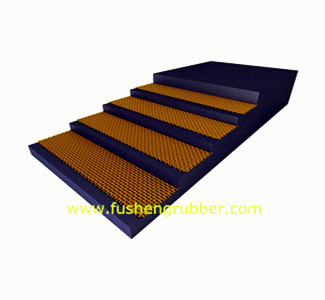

Pipe Conveyor Belt

Our Production Range:

Belt width:400mm-3000mm

Pipe Conveyor Belt

Features: Excellent flexibility , high speed, large angles of inclination transportation, unsealed transportation, eco-friendly.

Belt width and corresponding pipe diameter specification: unit (mm)

| BELT WIDTH | 360 | 600 | 800 | 1000 | 1100 | 1300 | 1600 | 1850 | 2250 |

| Pipe diameter | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 500 | 600 |

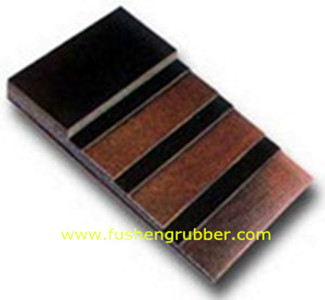

Physical property class of cover rubber:

| Performance class of cover rubber | Tensile Strength

MPa ≥ |

Elongation at break

% ≥ |

abrasion

mm3 ≤ |

Ozone Resistant | the tensile strength and elongation at break,s change rate after aging

% |

| T1、T2 | 10.0 | 350 | 200 | - | -45~+45 |

| D | 18.0 | 400 | 90 | No cracking | -25~+25 |

| L | 20 | 400 | 150 | No cracking | -25~+25 |

| H | 25 | 450 | 120 | No cracking | -25~+25 |

| A. Ozone resistant test condition: concentration (50±5)*10-8 (volume fraction), temperature (40±2)℃, elongation (20±2)%, time 96h.

B. hot air aging test condition: D and H type pipe conveying belt 70℃ *168h; T1 type pipe conveying belt 100℃*168h; T2 type pipe conveying belt 125℃*168h. |

|||||

| Note: D-High Abrasion;H-anti-tear;T1-Heat Resistant under 100℃;T2-High Resistant under 125℃;L-Moderate abrasion. | |||||

The Type D and Type H?belt should meet the requirement of the table 6.

| Item

|

Ply to Ply

|

transition part to Ply

|

cover rubber to ply | |

| Thickness of cover≤1.5mm | Thickness of cover> 1.5 | |||

| Maximum value of all samples,≤ | 20 | 20 | 20 | 20 |

| Average value of all samples,≥ | 8.0 | 8.0 | 5.0 | 6.0 |

| Minimum value of all samples, ≥ | 7.4 | 7.4 | 4.4 | 5.4 |

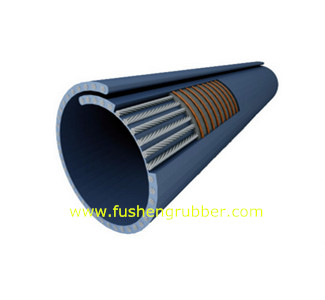

Steel Cord pipe conveyor belt

| Nominal diameter(mm) | Φ200 | Φ250 | Φ300 | Φ350 | Φ400 | Φ500 | Φ600 | Φ700 |

| Outer Diameter(mm) | 218 | 282 | 308 | 361 | 457 | 543 | 640 | 728 |

| Belt Width(mm) | 800 | 1000 | 1100 | 1300 | 1600 | 1850 | 2250 | 2450 |

Tensile Strength and belt width specification

| TEM | ST630 | ST800 | ST1000 | ST1250 | ST1600 | ST2000 | ST2500 | ST2800 | ST3150 | ST3500 | ST4000 | ST4500 | ST5000 |

| Longitudinal tensile strength (N/mm) | 630 | 800 | 1000 | 1250 | 1600 | 2000 | 2500 | 2800 | 3150 | 3500 | 4000 | 4500 | 5000 |

| Maximum diameter of steel cord (mm) | 3.0 | 3.5 | 4.0 | 4.5 | 5.0 | 6.0 | 7.2 | 7.6 | 8.1 | 8.6 | 8.9 | 9.7 | 10.9 |

| Pitch of steel cord(mm) | 10±1.5 | 10±1.5 | 12±1.5 | 12±1.5 | 12±1.5 | 12±1.5 | 15±1.5 | 15±1.5 | 15±1.5 | 15±1.5 | 15±1.5 | 16±1.5 | 17±1.5 |

| Top cover thickness (mm) | 6 | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 10 | 10 | 10 | 10 | 10 |

| Bottom cover thickness (mm) | 6 | 6 | 6 | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 10 | 10 | 10 |

| Belt width (mm) | Number of steel cord | ||||||||||||

| ST630 | ST800 | ST1000 | ST1250 | ST1600 | ST2000 | ST2500 | ST2800 | ST3150 | ST3500 | ST4000 | ST4500 | ST5000 | |

| 800 | 75 | 75 | 63 | 63 | 63 | 63 | 50 | 50 | 50 | 50 | |||

| 1000 | 95 | 95 | 79 | 79 | 79 | 79 | 64 | 64 | 64 | 64 | 64 | 59 | 55 |

| 1100 | 105 | 105 | 87 | 87 | 87 | 87 | 69 | 69 | 69 | 69 | 69 | 65 | 61 |

| 1300 | 124 | 124 | 103 | 103 | 103 | 103 | 83 | 83 | 83 | 83 | 83 | 77 | 72 |

| 1600 | 151 | 151 | 126 | 126 | 126 | 126 | 101 | 101 | 101 | 104 | 104 | 96 | 90 |

| 1850 | 177 | 177 | 147 | 147 | 147 | 147 | 119 | 119 | 119 | 119 | 119 | 111 | 104 |

| 2250 | 181 | 181 | 181 | 181 | 145 | 145 | 145 | 145 | 145 | 137 | 125 | ||

| 2450 | 197 | 197 | 197 | 197 | 158 | 158 | 158 | 158 | 158 | 148 | 139 | ||